PanXome: A Company on the Rise

We are all familiar with the medicine commercials that profess a miracle cure only to spout off a litany of side effects at the end. Dr. Jeff Skolnick of PanXome set out to solve that problem. Dr. Skolnick joined Georgia Tech’s faculty approximately eleven years ago as the Director of the Center for the Study of Systems Biology Program. “The thought at the time,” said Dr. Skolnick, “that it should be a great university, not merely a great engineering school and one of the areas that they had identified at the time was Biology because it was becoming increasingly quantitative. And what do engineers do? They build devices! There was a very strong existing computer science program… so it was a natural next step.”

We are all familiar with the medicine commercials that profess a miracle cure only to spout off a litany of side effects at the end. Dr. Jeff Skolnick of PanXome set out to solve that problem. Dr. Skolnick joined Georgia Tech’s faculty approximately eleven years ago as the Director of the Center for the Study of Systems Biology Program. “The thought at the time,” said Dr. Skolnick, “that it should be a great university, not merely a great engineering school and one of the areas that they had identified at the time was Biology because it was becoming increasingly quantitative. And what do engineers do? They build devices! There was a very strong existing computer science program… so it was a natural next step.”

Dr. Skolnick has spent his career developing algorithms, which model proteins so that their function and relationship to diseases and drugs can be understood and accurately predicted.This is how PanXome was born. “You know how science is, it’s sort of like things don’t work, they don’t work and then all of the sudden it starts to take off and you’ve got to get into the exponential part of the growth curve if you’re lucky.” PanXome is one of the things that does work. Dr. Skolnick describes the complicated process as looking at craters on the moon. “Well if you imagine these small molecules binding into these pockets, like craters on the moon you think, you fit into the crater and life is great. But if every crater is special it should be one molecule one target, like a Swiss watch.” Dr. Skolnick and his team discovered that this presumption was not necessarily true. Instead, PanXome is able to show that there are only 500 small molecule binding pockets in nature. “So this is a wonderful opportunity then,” says Dr. Skolnick, “If you have one molecule you don’t want to simply look at the protein of interest, you want to look at everything else as well. Whom am I interacting with that I want and whom am I interacting with that I don’t want?”

This breakthrough of this predictor structure has several astounding implications, one of which is that it will allow for fewer screening runs with a much higher rate of return. “Rather than thousands, or tens of thousands, or millions we screen between 50 and 100 molecules, and we know when it’s going to work. I may not be able to tell you which of these 50 are going to be the magic ones, but I know if there’s no point or I have a pretty good guess – maybe one in five is going to hit.” With PanXome’s screening process, medicinal chemists can predict which side effects their drug will cause, which ones will prevent them from receiving FDA approval, and allow them to target the proteins that will not have dangerous side effects.

Though this may seem small to those outside of the pharmaceutical industry, this relieves a major source of pain. Not only does it decrease the amount of time spent in testing, but it increases the chances that a drug will pass safety. The first rule of drug creation, says Dr. Skolnick, is do no harm. “Obviously pharmaceutical companies work very hard to mitigate this risk,” says Dr. Skolnick, “but in spite of that one in three drugs will fail safety. So if you had a way of de-risking or saying this is one that is very likely to fail safety and this is one that is probably going to pass it.” Because PanXome can look across the majority of the human exome they can suggest which molecules are going to pass safety with an 80% success rate.

As they continue to grow, PanXome is exploring other uses for their algorithm, including diagnostics, but Dr. Skolnick’s main focus remains in predicting side effects and efficacy of new drugs. To learn more about their impressive breakthroughs, please visit their website at http://panxome.com/.

Interview with I-Corps Graduate: TC Poly

TC Poly is developing the world’s highest thermal conductivity pure plastic material for thermal management application in the batteries and LED markets. The proprietary material boasts a thermal conductivity 25x greater than conventional plastics, allowing for advanced cooling capabilities. The material is lightweight, electrically insulating, and can be processed using traditional injection molding techniques. By replacing standard plastic components with our material, customers can achieve enhanced thermal management capabilities and unrivaled design flexibility.

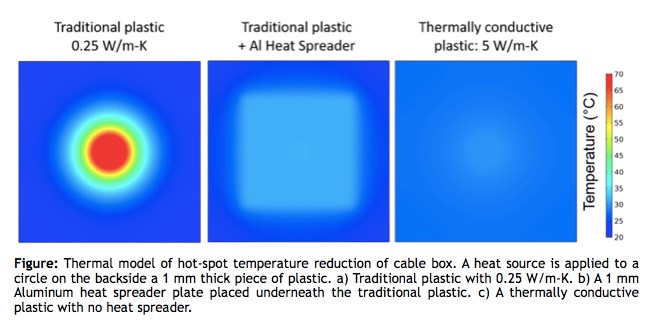

Heat removal in electronics is increasingly difficult because of the ever-growing computing power and the limited space for heat sinks as electronics become smaller and lighter. Hence, thermally conductive plastics have emerged as an attractive class of low-cost materials to replace traditional plastics and reduce device operating temperatures. The market for thermally conductive plastics is expected to grow to $1.9 billion as manufacturers seek out more cost-effective heat dissipation solutions. Through customer discovery in the NSF I-Corps program, TCPoly has learned that the market is being driven by the need to reduce chip, battery, and touch temperatures in consumer electronic devices. The below figure demonstrates the power of the TCP casing to dissipate heat. A large hot spot occurs when a local heat source is applied underneath a normal non-

Heat removal in electronics is increasingly difficult because of the ever-growing computing power and the limited space for heat sinks as electronics become smaller and lighter. Hence, thermally conductive plastics have emerged as an attractive class of low-cost materials to replace traditional plastics and reduce device operating temperatures. The market for thermally conductive plastics is expected to grow to $1.9 billion as manufacturers seek out more cost-effective heat dissipation solutions. Through customer discovery in the NSF I-Corps program, TCPoly has learned that the market is being driven by the need to reduce chip, battery, and touch temperatures in consumer electronic devices. The below figure demonstrates the power of the TCP casing to dissipate heat. A large hot spot occurs when a local heat source is applied underneath a normal non-

conductive plastic (Figure a). A common solution in consumer electronics is to add a metal plate underneath the plastic adding cost, complexity, and weight to the casing (Figure b). By making the electronics casing out of the TCP material (Figure c), the temperature is reduced to the same level or lower than with a metal plate but without the additional weight and complexity. In this simulation, by switching to the TCP material the casing temperature is reduced from 68°C to 29°C without adding any additional weight or manufacturing steps to the electronics part. This temperature reduction has been verified in lab testing and TCPoly is now working with several partners in the consumer electronics industry to develop prototypes for applications testing.

Interview with Co-Founder Thomas Baugher

Can you tell me a little bit more about your background?

I’m from Ohio originally by way of Indiana and Texas. I went to Purdue for undergraduate and UT-Austin for my Master’s. Prior to coming to Georgia Tech for my Ph.D. I spent 5 years working as an automotive engineer. I loved cars, but I really wanted to work on a next-generation technology, so I decided to come back to school to get my degree and do research in nanomaterials. Research in nanotechnology is so motivating to me because the possibilities are so big. In a refined technology like an internal combustion engine improvements of a single percent are meaningful, while in making a new nanomaterial you might change a property by a factor of 50. I also find the startup environment exciting, because things can be very dynamic. I get to make new materials, build test rigs, write code, talk to customers, and develop a strategy. Constantly changing hats keeps things fun.

What sparked the idea for TCPoly?

My co-founder Matt Smith and I were both working on thermally conductive polymers in the same graduate research group for four years, and we were both interested in commercialization. Prior to my graduation at the end of 2015, we decided we should try I-Corps to see if our idea had any merit for commercialization. We found that the initial application of our technology probably wouldn’t have good traction, but that it could easily be adapted to a different application. I decided to stay at GT instead of taking a job at a semiconductor company on the West Coast because I think we have a great chance at being successful in commercializing this technology. Matt is a born entrepreneur, and he enrolled in graduate school with the intention of starting a company; he’s been leveraging GT’s great resources throughout his graduate studies including VentureLab startup gauntlet, ATDC seminars, and the TiGER program to help us get a head start on our company.

How do you describe your technology to someone who does not have a background in tech?

We are making plastics that can keep your electronic devices cooler. Our material can be used for a variety of applications such as the case of a cell phone, the frame of a cable box, an LED light housing, or the casing of a battery. By changing the structure of these materials we can make them conduct heat more like a metal than a plastic, but lighter and less expensive.

During the I-Corps program, what did you find most surprising? Did you have a major pivot?

We had been working with several major electronics companies throughout our research so we felt we understood the industry fairly well and the challenges of commercialization. During the I-Corps program, we quickly realized that we understood the some of the technical challenges, but not the business side or the degree of cost sensitivity. We did go through a major pivot at the end of the program. We stayed in the electronics market but shifted the way our materials would be used. That pivot led us to the current version of the technology we’re making today.

What was the most consistent feedback that you got from your Customer Discovery?

I-Corps was a very valuable experience for us because it taught us to look for how our material can enable parts to be re-engineered for better performance and cost savings. Thinking in terms of value propositions instead of technical specifications as the instructors would say. The top item of importance was consistently cost. Even when an engineer would get really excited about how our technology would enable better performance of his device, the sentence would still end with “…and if you could make it cheaper too, that’d be great!” We’ve carried that lesson into the way we’re currently working on scaling our material to keep costs as low as possible.

What is your goal for TCPoly?

I think we are at an exciting time to be starting a company with a new type of plastics for electronic devices. People in industry are only now starting to think that maybe the housing of a device could help dissipate heat, and our material is well-suited to become established on the ground level of this shift in thinking for electronics packaging. With the great resources around Atlanta and GT and some great mentors, my partner and I want to grow this business in Georgia and see how far we can take it.

Frog Saliva, Cat Tongues, and Earwax: VentureLab’s Person to Watch

“Frog tongues use a sticky fluid to adhere to prey, cat tongues are different. The tongue is also very soft, not as soft as frog tongues, but the cat tongue has these sharp barbs in it that allow them to groom their fur really efficiently and rip meat off of bones and things like that.”

This is not your typical coffee shop chatter, but this is a conversation with which Alexis Noel, a Ph.D. candidate at Georgia Tech, has become extremely comfortable.

Alexis arrived at Georgia Tech as an eager undergrad, excited to study aerospace engineering. Not long after she began, she realized that, though she loved her aerospace classes, she was jealous of her Mechanical Engineering friends who “got to work with their hands.” She kept an Aerospace minor but made the switch in her sophomore year to Mechanical Engineering. She dove head-first into her new major by enrolling in Georgia Tech’s BS/MS program, a five-year program that allows Mechanical Engineering students to receive both a Bachelor of Science and Master of Science with five years of course work. After completing her Bachelor Degree, Alexis knew that she wanted to continue her studies at Georgia Tech, but wasn’t sure what path to take. That is when she met Dr. Hu.

“I’m working with ants,” one of Alexis’ good friends told her one day. “ANTS? In an engineering lab?” Alexis was stunned. After only a few meetings with Dr. Hu, Alexis had found her intellectual home. “It was a great environment to work and I was getting to have fun playing with frogs,” said Alexis. In her time in Dr. Hu’s Biolocomotion lab, Alexis has had the opportunity to work with all manners of creepy crawlies. In a recently published paper, Alexis discusses the frogs’ use of viscoelastic tongue and non-Newtonian saliva to catch their prey. Or, as her NPR interview so succinctly put it “Pretty disgusting snot-like spit’ lets frogs catch their prey.”

Alexis’ most recent project was inspired by her own furry friend, rather than a lab subject. One day Alexis noticed that her house cat appeared to be wrestling with a blanket on the couch. Upon closer inspection, she found that the cat’s tongue was stuck to a microfiber blanket. After detangling her cat, Alexis asked herself a question that seemingly few have asked; “What is going on with my cat’s tongue?” After diving back into her research, Alexis discovered that her cat’s tongue is not only unique but may have more practical applications. After studying the makeup of several cat tongues, including a tiger’s tongue donated by the Atlanta zoo, Alexis has created a 3D-Printed tongue that can do a lot more than detangle fur. Among its other applications, Alexis is excited to get back to her aerospace roots by working on adapting her cat tongue technology to be able to pick up rocks and debris in outer space. Alexis is excited to explore all of the ways that she can commercialize her technology in the future and plans to work closely with VentureLab to guide her through the process.

Georgia Tech startups leading the way

In January 2016, Google Capital led a $75 million funding round for Pindrop Security, a Georgia Tech spinout. In June, another Georgia Tech spinout, Clearside Biomedical, focused on drug delivery, went public and raised $60 million. VentureLab is proud to be part of the innovation success ecosystem, which brings business experience, funding, and people together to create startups based on Georgia Tech research.

To understand how these large successes happen, here is Clearside’s story: Mark Prausnitz received his doctorate from the Massachusetts Institute of Technology. He is a Georgia Tech Regents Professor, has a large lab filled with researchers and is credited with more than 30 patents. He runs Georgia Tech’s Laboratory for Drug Delivery. To quote his lab’s website:

“Dr. Prausnitz and his colleagues carry out research on biophysical methods of drug delivery, which employ microneedles, ultrasound, lasers, electric fields, heat, convective forces and other physical means to control the transport of drugs, proteins, genes and vaccines into and within the body.”

Prausnitz’ approach to drug delivery is disruptive, innovative and constantly evolving. He collaborates with researchers at Emory, the Centers for Disease Control, and major pharmaceutical companies. In one of his many collaborations he worked with the late Dr. Henry Edelhauser, former Emory Eye Center director. Together, they developed a microneedle to solve a drug delivery problem for patients who suffer from eye diseases. The challenge was to control drug doses to a small area in the back of the eye. By delivering the drug in such a targeted fashion, patient outcomes were expected to be better because of a smaller dose resulting in fewer adverse side effects.

VentureLab worked with Prausnitz and Dr. Edelhauser to arrange a series of Georgia Research Alliance commercialization grants in 2010 and 2011. When the technology proved capable in laboratory tests, VentureLab then helped identify CEO Dan White in 2011 and with his leadership, Hatteras Ventures invested $4mm in founding equity. The IPO came 5 years later. More innovations for a variety of diseases are expected from Clearside.

Future or current entrepreneurs, researchers and business leaders are welcome to become part of this Georgia Tech VentureLab process. Please reach out to any of our Principals at info@venturelab.gatech.edu or https://venturelab.gatech.edu/about-us/.

Regional I-Corps program open to community teams

Georgia Tech and its partner universities are hosting an I-Corps cohort at Georgia Tech in October. This cohort is unique in that in addition to traditional university commercialization teams, it’s open to teams that aren’t part of a university ecosystem. If you are a team with a technology startup and you want an opportunity to experience the I-Corps experience at no cost, please send us an application. Seats are limited.

If you have further interest in speaking with the winning teams or VentureLab for future participation, reach out to info@venturelab.com.

WEAV3D, I-Corps program graduate, focuses on delivering first prototype

WEAV3D, a Georgia Tech team mentored by VentureLab principal Jon Goldman, recently completed NSF’s I-Corps program to find a product-market fit for its emerging composites weaving technology.

The company’s initial business thesis was that its composites manufacturing process would be valued by the aerospace industry, which is always looking to shed weight in aircraft. After extensive Customer Discovery, with both manufacturers and integrators of manned and unmanned aircraft, the compa

ny determined that gaining certification for new parts would take a tremendous amount of time, and have all the market risk associated with Federal Aviation Administration and military certifications. As a result, the team pivoted from this market segment to examine applications in the automotive industry. After three trips to the Detroit area, the team validated a huge pain in the industry as original equipment manufacturers (OEM) grapple with looming impacts from the Corporate Average Fuel Economy (CAFE) standard.

WEAV3D is now focusing on delivering the first prototype machine by year’s end where small demonstration samples can be delivered in the hopes of landing a first ‘design-win’ with one of the OEMs or design/engineering houses such as Roush Engineering or Pratt-Miller. The team plans to build a full-scale machine that could handle the delivery of full-scale parts such as automotive hoods, doors, roofs, and trunks, thus displacing large, expensive metal-stamping production lines with a far cheaper CAPEX solution.

If you’re interested in what WEAV3D is up to, or if your team might benefit from I-Corps training, contact us at info@venturelab.gatech.edu.